ALL VENDORS AND CONTRACTORS MUST READ AND AGREE TO THE FOLLOWING TERMS AND CONDITIONS:

VANE BROTHERS VENDOR & CONTRACTOR INSURANCE REQUIREMENTS

Vane personnel utilizing any vendor or contractor must first verify that they have an approved Certificate of Insurance (COI) on file with the Insurance and Claims Department. All vendors and contractors must receive approval from the Insurance and Claims Department prior to working for Vane. Certificates of Insurance should be emailed to insurancecertificates@vanebrothers.com.

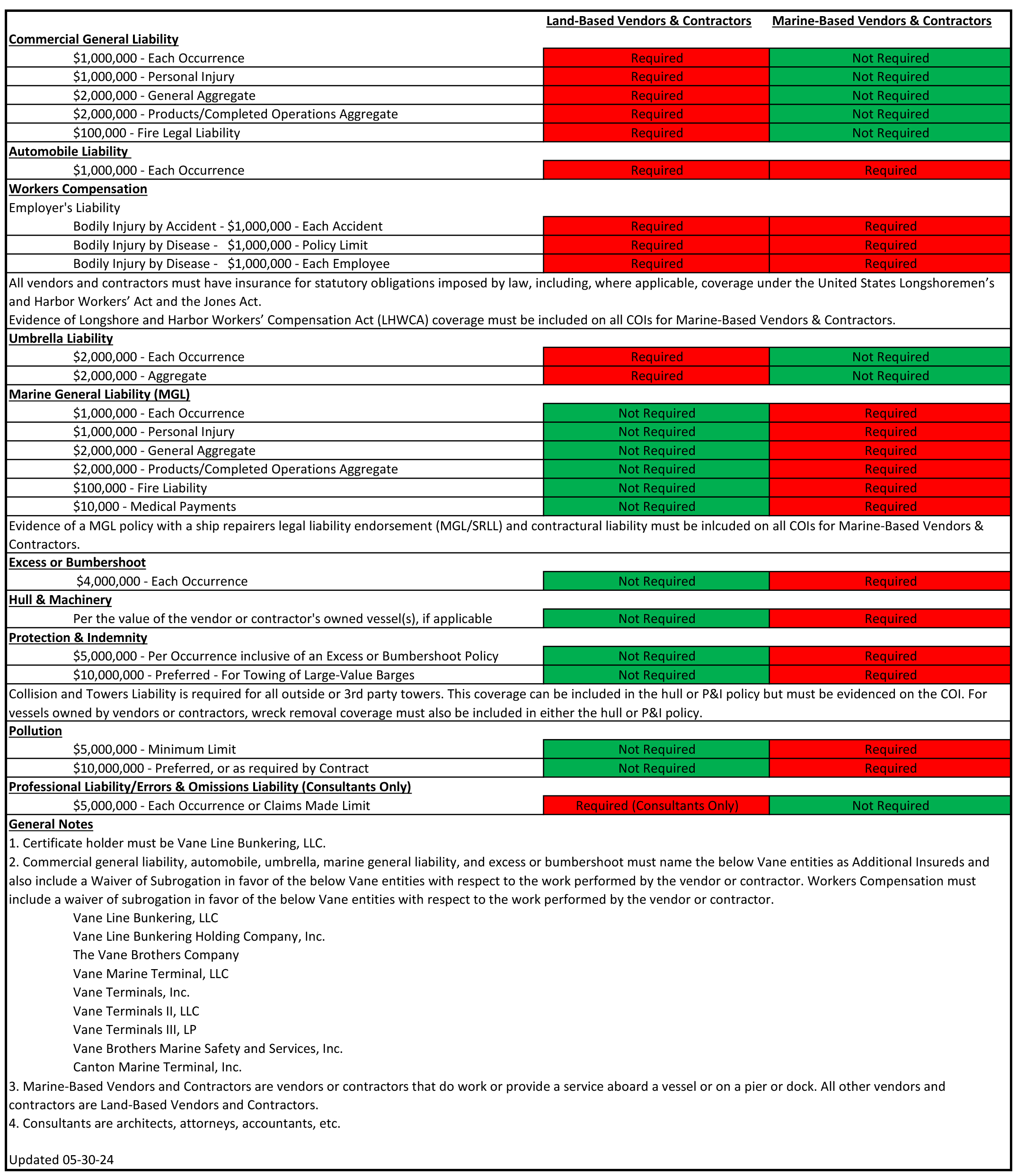

Insurance Requirements for Vendors and Contractors – Land-Based & Marine-Based Coverages

______________________________________________________________________________

VANE BROTHERS HEALTH, SAFETY & ENVIRONMENTAL (HSE) VENDOR SAFETY POLICY

All Contractors and Vendors must adhere to the following general safety rules:

1. Working safely is a condition of hire at Vane Brothers and its various divisions. This applies to all employees, vendors and contractors.

2. Reporting incidents and unsafe conditions – Every vendor and contractor has the authority and responsibility to report unsafe conditions. All incidents and unsafe conditions must be immediately reported to the task supervisor, vessel Master or Port Captain/Engineer regardless of the severity. Call Vane Traffic/Dispatch at 410-631-5096 to speak with the Operations Duty Manager.

3. A Safety Orientation is required for all visitors and contractors who will be getting underway aboard the vessel. This must be completed upon initial boarding and properly logged in the Captain’s Log.

4. Job Safety Analysis (JSA) – A JSA is required for all routine and non-routine tasks when Vane crewmembers are working alongside, or in direct observation of, contractors and vendors. The JSA shall be conducted by the Vane vessel Master or his/her designated crewmember and must be properly documented and logged.

5. Vendors must adhere to the requirements of Vane’s Company Operations Manual and Health and Safety Plan at all times. Tasks will be supervised by Vane personnel, who shall monitor the tasks for compliance with all Vane policies. Access to Vane policies is available onboard Vane vessels and at Vane terminals and facilities, and shall be provided to vendors when a request is made to Vane’s Health, Safety & Environmental (HSE) department.

These policies include but are not limited to:

-

- Fall Overboard Prevention – This is critical for keeping all crewmembers safe. Wear a work vest at all times when working on deck and handling lines, or when the risk of a fall overboard is present, such as while boarding and disembarking.

- Fire – All activity must be closely monitored for the risk of fire. Fire watches must be posted for hot work tasks, and all fires must be immediately reported to the vessel Master and fought with available equipment until help arrives.

- Personal Protective Equipment (PPE) – PPE must be worn when using power tools, air lines, welding/cutting equipment, and/or any equipment that increases the risk of personal injury.

- Hearing protection must be worn in the machinery space and when in proximity to any running machinery. This may inhibit communications and must be discussed at the Job Safety Analysis (JSA) meeting.

- Footwear must be non-slip with ankle support and toe protection. Sneakers, flip-flops, etc. are not permitted to be worn on Vane vessels or property.

- Gloves must be worn when handling chemicals, cargo, mooring lines and at all times when contact with foreign substances may be hazardous to health.

- Respiratory protection must be properly fitted and in accordance with manufacturer recommendations. If working in a space where harmful vapors may be present, proper respiratory protection is required to be worn and maintained at all times while in the space.

- Clothing must be appropriate for weather, flame resistant (if required within that area) and tight fitting to avoid hazards of rotation machinery.

- Hard hats are required for all work involving lifting equipment and also anytime there is the risk of objects falling from heights.

- Eye Protection shall be always worn when working with power tools.

- Housekeeping and Trip Hazards – Decks and walkways must be kept free of slip and trip hazards. Working areas must be kept neat and orderly to prevent crewmembers, vendors and contractors from tripping.

- Prevention of Fall from Heights –

- Handrails must be used at all times when on stairs. Permanently installed deck railings must be used when traversing the deck.

- Always face stairs and vertical ladders when going up or down.

- Never attempt to use the stairs when both hands are full or your vision is obstructed.

- Do not walk on pipelines or conduits.

- Use inboard walkways on tank barges to avoid unprotected edges.

- Scaffolding must be erected and evaluated by a competent person.

- Ladders must be adequately rated, in good working order, and properly staged with secure footing and by being tied off. Ladders and gangways must be used according to their labels and manufacturer’s instructions.

- Confined and Restricted Spaces –

- Confined Space entry and/or work requires a valid Certified Marine Chemist (CMC) certificate listing “safe for hot work” and/or “safe for entry” as applicable.

- Restricted space entry, as defined by the Vane Brothers Health & Safety Plan, requires the use of a restricted space access permit or CMC certificate listing “safe for entry.”

- Smoking – Smoking is not permitted aboard vessels or property except in designated and labeled areas.

- Lighting – Work areas and walkways must have adequate lighting to avoid slip, trip and fall hazards. Portable lighting must be provided and properly staged if existing lighting is not adequate.

- Training – Vendors and Contractors must receive basic safety and technical training according to OSHA and manufacturer-specific regulations and requirements.

- Drugs and Alcohol – The use and possession of drugs and alcohol is forbidden at all times while on Vane Brothers property, equipment or vessels.

- Electronic Devices – All electronic devices that are not rated intrinsically safe must be powered down prior to entering a hazardous atmosphere or hazard zone as defined on the barge.

______________________________________________________________________________

VANE BROTHERS OPERATIONAL TECHNOLOGY SECURITY REQUIREMENTS

Vendors and service technicians must be approved by the assigned Port Engineer, Port Captain or Fleet Maintenance Manager before working on any operational technology or electronic equipment, including main engine propulsion where fitted with a computer.

-

- Vendors and service technicians who access Vane Brothers Information Technology or Operational Technology are required to comply with one of the following in accordance with 33 CFR § 101.650(d)(3):

a. Complete Vane's cybersecurity training,

b. Complete a cybersecurity training program that has been evaluated by Vane's Cyber Security Officer, OR

c. Be escorted (as defined in 33 CFR § 101.650(d)(3), either physically or remotely, by a Vane employee who has received Vane's cybersecurity training.

- Equipment must be checked for proper operation before the technician leaves the vessel.

- Any issues or signs of improper operation after servicing must be reported.

- Manufacturer-approved technicians’ laptops or meters shall be used while on board.

- No unapproved “add-ons” or remote connections shall be allowed without permission from the Port Captain or Fleet Maintenance Manager.

- Anomalies found in machinery operation after servicing must be reported.

- Any signs of remote operation of electronic equipment, including main engine propulsion systems, must be reported immediately and the vessel’s systems monitored or, if necessary, secured until the issue can be resolved. This does not include remote access of the wheelhouse laptop by the IT department when necessary.

______________________________________________________________________________

VANE BROTHERS INFORMATION TECHNOLOGY ACCEPTABLE-USE POLICY

All employees and agents of vendors/contractors who will access Vane Brothers information technology in the course of their work for Vane are required to acknowledge their compliance with Vane’s Information Technology (IT) Acceptable-Use Policy prior to accessing any Vane IT tools, systems or services.

The term “information technology” is defined as any device or software that is used to access Vane’s network, electronic messaging storage, transmission, or use of all computer files, and all activities relating to the concept of the Internet. This includes Vane’s Intranet and all external networks accessible to users, along with Operational Technology (OT) such as engines, marine electronics, etc.

POLICY:

Vendor personnel:

1. Who access Vane Brothers Information Technology or Operational Technology are required to comply with one of the following in accordance with 33 CFR §101.650(d)(3):

a. Complete Vane's cybersecurity training,

b. Complete a cybersecurity training program that has been evaluated by Vane's Cyber Security Officer, OR

c. Be escorted (as defined in 33 CFR § 101.650(d)(3), either physically or remotely, by a Vane employee who has received Vane's cybersecurity training.

2. Have no expectation of privacy in any electronic communications, use of Vane Brothers property or Internet access. Vane reserves the right to review, audit or monitor any information technology used by vendor personnel.

3. Shall use only accounts authorized by Vane and access only those resources for which they are authorized.

4. Must access all user-level systems through a password-protected account that conforms to the following guidelines:

a. Passwords shall remain confidential. Passwords are not to be shared, except as specifically requested by individual department heads.

b. Passwords should never be displayed, printed, or otherwise recorded in an unsecured manner. User account and password information must not be inserted into any form of electronic communications or storage, without using encryption methods and tools approved by Vane’s IT Department.

c. A standard, default password is not to be used for groups of users.

5. Are personally responsible for safeguarding their account and log-on information.

6. Are not permitted to script their user IDs and passwords for log-on access.

7. Are not permitted to allow another person to log on to any computer utilizing their personal account, nor are they permitted to utilize someone else’s account to log on to a computer. Authorized system or service accounts may be used by multiple people.

8. May not leave their workstation logged on to the network while away from the area. Vendor personnel may elect to lock the workstation rather than logging off when leaving for very short periods of time.

9. Shall execute only applications that pertain to their specific contract work.

10. Shall promptly report log-on problems or any other computer error to IT Support at 410-735-8119.

11. Shall promptly notify the IT Director if they have any reason to suspect a breach or potential breach of security.

12. Must have approval in writing from the IT Director (or Company Security Officer, Head of Maintenance or Vice President of Operations when connecting to engines) when:

a. Attaching any device to, or removing it from, the Vane network;

b. Installing any type of encryption device or software on, or removing it from, any Vane hardware;

c. Installing or removing any computer software;

d. Attaching any network or phone cables to, or removing them from, any Vane device;

e. Removing data from the Vane premises; and

f. Intercepting or monitoring network traffic by any means, including network sniffers.

13. Shall not delete, disable or bypass any authorized encryption device, and anti-virus or other software program, installed on Vane hardware.

14. May not copy any data and/or software from any Vane resource for personal use.

15. Shall not install any hardware (devices or software) that violate the NDAA (use of technology by prohibited manufacturers).

16. May not give out any Vane computer information to anyone except other vendor personnel needing the information to complete tasks and who have signed this agreement. Computer information includes, but is not limited to: IP addresses, security configurations, etc.

17. Must erase or destroy all data storage media prior to disposal.

18. Shall not attempt to obtain or distribute Vane system or user passwords.

19. Shall ensure any media (when authorized to connect to Vane information systems or OT) is free of virus/malware or unsafe programs/software.

20. Shall ensure access to store Vane data outside of Vane’s network is protected by appropriate security measures (MFA/2FA).

21. Shall not attempt to obtain or distribute door passkeys to secured rooms at any Vane facility for which they are not authorized.

22. May not use Vane information technology to send or receive any threatening, obscene, abusive, or sexually explicit messages or pictures.

23. Are prohibited from causing Vane to break copyright laws.

24. Acknowledge acceptance of the above-referenced policies upon first using Vane information technology. Any vendor employee who violates any of these policies shall be subject to disciplinary action, including total removal from the Vane contract, as well as being subject to civil and criminal liability. Disciplinary action may include Vane requesting the vendor consider demotion, suspension or termination.